return to Blog

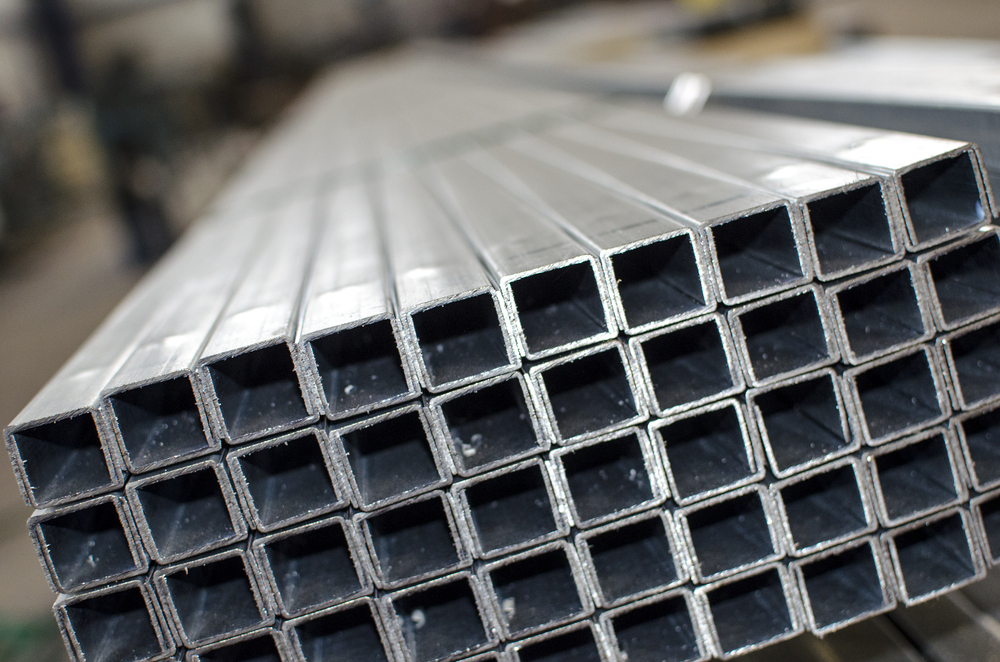

In construction and manufacturing, the choice of materials plays a crucial role in determining the success of a project. Sheet metal, integral to applications ranging from structural construction to the precision crafting machinery parts, is essential for durability and performance. This blog examines how the quality of sheet metal influences its durability, highlighting key factors that manufacturers, builders and contractors should consider to ensure their projects endure over time and against environmental challenges.

Selecting the appropriate grade of sheet metal is fundamental in determining the longevity and effectiveness of the final product. Different grades have unique properties that make them suitable for various applications—weather resistance for outdoor structures or thermal conductivity for heating systems. Here’s how understanding these grades can prevent future issues:

A reputable sheet metal supplier can help you select the most appropriate material for your specific needs, ensuring durability and cost efficiency.

The battle against corrosion is ongoing in metal works. The right treatments and coatings can dramatically extend the life of sheet metal by protecting it from environmental degradation. Here are some common solutions:

Corrosion resistance is about prolonging the product’s life and maintaining its appearance and structural integrity over time. A sheet metal supplier that offers corrosion resistance ensures that your materials are resilient against harsh conditions.

The thickness and tensile strength of sheet metal are crucial for determining its performance under stress. Choosing the appropriate thickness and a higher tensile strength grade significantly impacts the durability and safety of projects.

For example, using robust sheet metal for high-traffic areas ensures longevity and resistance to wear and tear. Making informed decisions about these properties is essential in the selection process, as they directly influence the structural integrity and longevity of the final product.

Precision Cutting

High-quality sheet metal allows for precise cuts that fit perfectly in complex assemblies, reducing waste and installation errors.

Consistent Quality

Uniform quality across batches ensures that every piece performs as expected, eliminating weak points in fabricated structures.

High precision in manufacturing processes translates to fewer adjustments during assembly and a more refined final product, aesthetically and functionally.

Steel structures can incorporate large windows and open spaces, creating an inviting atmosphere for businesses and customers alike. The overall building cost is reduced due to its ease of fabrication and installation. Fortifying commercial properties with structural steel ensures that these buildings remain competitive and appealing in the market.

The environmental impact of materials used in construction and manufacturing is increasingly being scrutinised. High-quality, recyclable sheet metals ensure a longer lifespan for products and contribute to a more sustainable industry practice.

By choosing recycled materials, businesses help reduce their operations’ environmental footprint, making sustainability a critical aspect of long-term durability

Enhancing residential security with structural steel protects inhabitants and adds value to the property. Homeowners can enjoy the benefits of a safer living environment without the frequent maintenance required by other materials.

At Top End Steel Supplies, we understand the critical role of quality sheet metal in the durability and success of your projects. Our steel manufacturers in Darwin supply top-grade metals tailored to your specific needs, ensuring that your constructions are built to last, even in the toughest conditions. Don’t compromise on the quality of your next project. Get in touch via our contact page or give us a call for more information. Let us help you build a lasting legacy with materials that match your ambition.