If you’re looking for professional steel fabrication and forming experts, it’s good to have at least a basic understanding of the processes that go into fabricating steel elements. Steel punching is a common technique that’s used to remove a scrap slug of metal from the workpiece to leave a hole or to create indentations in metal.

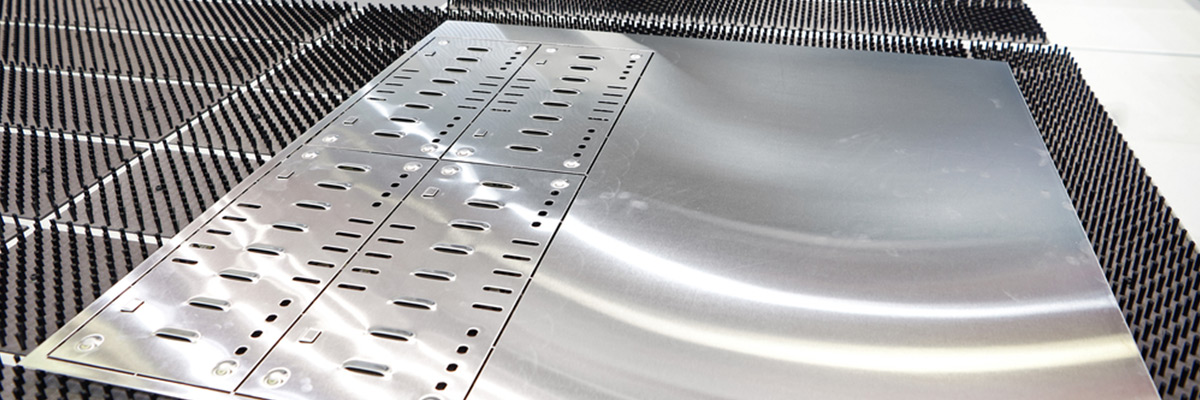

Steel punching is a technique used to punch a hole in steel workpieces. It’s an economical process that can be used to quickly produce accurate holes in metal at both medium and high production speeds. Holes of varying shapes and sizes can be produced using different kinds of steel punching. The process is most commonly used to punch holes in sheet metal, but it can also be used to punch holes in roll metal.

Steel punching involves a steel punch that’s made of hardened steel. Different sizes and shapes of steel punch will result in different sizes and shapes of hole in the steel workpiece. The steel punch pushes into and through the steel workpiece, creating a clean and accurate hole. The piece of material that is punched out is called the scrap, and this is usually collected for recycling after the punching process is complete. Steel punching can also be used to make indentations in metal.

The prick punch is probably the most commonly used steel punch today. A prick punch machine can be used to transfer paper patterns to metal, which can then be used as reference points during other fabrication processes. The punch is lined up and then tapped lightly with a small hammer, which creates slight indentations on the metal.

A centre punch can be used to make larger indentations in metal, particularly those that are large enough for drilling activities. Centre punches are heavier than prick punches and must be used carefully to avoid creating protrusions.

A drive punch can be used to remove damaged rivets, bolts, and pins. A drive punch usually has a flat face, with wide sides that taper down to the face. A similar kind of punch is the drift punch, which has a straight shank and is used for slightly different applications.

A transfer punch can be used to fit drill-locating holes in a steel template. Transfer punches are usually four inches in length, with a point that tapers initially before running straight. The tip of a transfer punch looks similar to that found on a prick punch.